BBQ potato chips were my first thought. A burning, mesquite note, like you smell in the air on a summer evening in the suburbs when everyone starts up their grills. It was earthy and little bit piney, but the flavor on the palate was sweet — caramel, toffee, and just a little burnt cinnamon. It was one of the most unique bourbons I had ever encountered.

Unfortunately, it will never be sold to the general public. RP5 #2, as it’s labeled internally, is merely a test batch for Maker’s Mark Private Select, a one-of-a-kind program hoping to uncover the future potential of wood in whiskey.

“When you’ve made one product for 65 years, it’s a new way of thinking about things,” says Jane Bowie, the distillery’s maturation specialist who spearheads the program.

As Bowie suggests, Maker’s Mark might not be the first distillery you think of when it comes to innovation. Most whiskey drinkers respect the company, which was founded in Kentucky in 1958 and is now owned by Beam Suntory; but its iconic, red wax-dipped, soft red winter wheat flagship bourbon was its only product for more than half a century.

In 2010, however, Maker’s Mark released Maker’s 46, a whiskey that longtime president Bill Samuels, Jr. hoped would cement his legacy as he approached retirement. Working alongside Maker’s Mark’s barrel maker, the Independent Stave Company, the distillers developed new techniques and technology.

They placed French oak staves in what Bowie describes as an industrial pizza oven, then slowly and lightly seared them using infrared heat. That process released a ton of caramel and vanilla notes in the wood, while eliminating many of the bitter tannins endemic to the wood species. Ten of those staves were placed on a hoop, plunged into a barrel of cask-strength Maker’s Mark, and then left to “finish” the whiskey for another couple of months. Richly flavored Maker’s 46 was both a commercial and critical success.

“That taught us that wood is such a powerful natural ingredient,” Bowie says. The team thought to itself, “‘Holy sh*t, there’s all this flavor in oak that is still untapped.’”

Bolstered by the success of Maker’s 46, the distillers began discussing plans for a larger wood-finishing program. Bowie and her small team started by asking themselves which wood flavors and sensations they wanted to amplify. Extracting vanilla seemed obvious. Was it possible to get more fruit notes? Producing a bigger mouthfeel and longer finish was also a top desire.

“Could you deconstruct Maker’s, could you create virgin oak staves that drive the Maker’s into these different flavor camps?” Bowie wondered. “Was this even possible?

It was, and, by 2014, Independent Stave had presented Maker’s Mark with a few dozen different stave “flavors.” The distillery whittled those down to eight favorites. With 10 total finishing staves needed per barrel, someone casually wondered how many different combinations would be possible. The answer was 19,448. Way too many.

The group spent another six months getting it down to four favorites to join the Maker’s 46 stave. That gave them 1,001 possible combinations. Bowie claims their six-person tasting panel has tasted every single one of those, just to make sure “you couldn’t f*ck it up.”

By “you” she means private barrel buyers, a target audience for the customized spirits. Single-barrel programs have become a key component of American whiskey culture in the last few years. Today, all the major Kentucky distilleries allow bars, restaurants, retailers, and even certain private groups or individuals to purchase an entire barrel of, say, Four Roses or Wild Turkey’s Russell’s Reserve. It’s a significant investment for any devotee: A 53-gallon barrel usually breaks down to about 150 to 225 bottles, depending on evaporation. Private barrels from Four Roses, Wild Turkey, and Maker’s Mark start at around $7,500 or so.

Maker’s Mark is currently the only company that allows consumers to purchase a product that otherwise doesn’t exist in its portfolio, one fine-tuned to that individual’s taste. (“Make your own Maker’s,” the distillery proclaims in its promotional materials.)

The first Private Select liquid was officially offered in November 2015 to select retailers in Kentucky and Illinois. That’s when I first heard about the program, too. I’ll be honest: I thought it sounded like a gimmick. And so I ignored quite a few emails from the distillery’s PR team over the ensuing year or so, writing it off as a marketing ploy.

When I finally did taste through the five bourbons produced by the different staves, in summer 2018, I was blown away by their diversity. By simply adding 10 different staves to barrels of Maker’s Mark Cask Strength for just nine additional weeks, the distillers created an incredible range of spirits. If Maker’s 46 was about creating a well-balanced finish in cask-strength bourbon, the other four staves were about exaggerating certain flavors and sensations.

The stave labeled “Baked American Pure 2” is vanilla amped up to 11. “Toasted French Spice” is baking spices incarnate. “Seared French Cuvée” could easily be confused for Cognac, dry and spicy with a huge mouthfeel, and rich though surprisingly not dark in color. “Roasted French Mocha” has a massive finish — the taste of chocolate, coffee, and almonds lingers in your throat for minutes after you sip it.

Ambitious bars and restaurants have begun using the program to customize the spirits in their signature cocktails. Avant-garde cocktail bar The Aviary, for instance, which has locations in NYC and Chicago, selected a stave combination that it thought induced prominent cinnamon and chocolate notes — perfect for the bar’s cinnamon- and mocha-chai-tea-heavy Cloche Encounters cocktail. In Nashville, Henley restaurant picked a sweeter stave combination specifically meant for their house Manhattan.

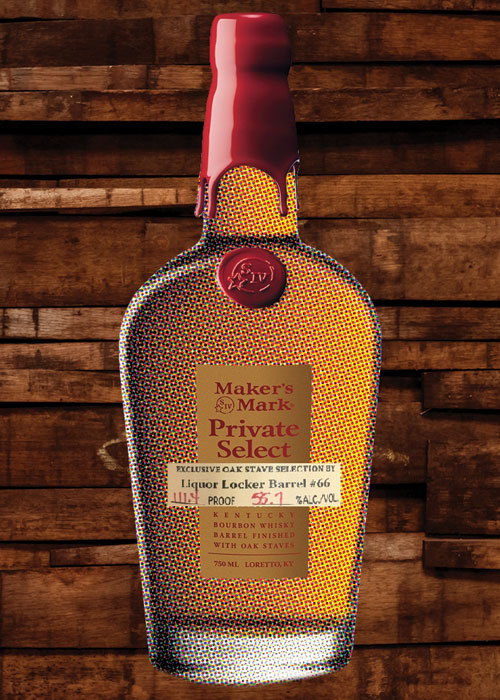

Other outlets are serving their specialized spirits neat. The Private Select bottle looks completely different from the standard, boxy Maker’s Mark bottle, and stands out on shelves and back bars in tony establishments like Dumbo House, a private club in Brooklyn.

“What we’ve learned in the last five years, holy cow, we’re going to open Pandora’s box and see where we go,” says Bowie. She’s tested over 500 different stave experiments since picking those initial five.

To create so many different options, Independent Stave has had to develop new wood techniques and test numerous cooking methods. Oak generates different flavors at different times and temperatures. One of the new techniques I’ve been able to learn about includes the specific shape of the Seared French Cuvée staves. They look like ruffled potato chips, giving them 22 times more surface area than a typical stave.

Many of the other techniques, however, remain a secret — even to Maker’s Mark. The company doesn’t know exactly how Independent Stave creates each stave, or which species of oak is specifically used. While Bowie won’t divulge the countless, sometimes proprietary ways Maker’s Mark and Independent Stave treat their wood, she does offer a helpful analogy.

“Think about how many different ways there are to cook a steak,” she says. “Convection, you can broil, or sear. Soft boil or sous-vide. Even, think about ceviche — think about how chefs use acid to break down and change the chemical makeup of fish. So how you’re treating the raw ingredient matters just as much as how you cook it.”

Of course, if some 500 new staves have been created already, some 495 or so have never been made available for public consumption. (Like that RP5 #2 I tasted in 2018.) Maker’s Mark has spent three years trying to develop a better Roasted French Mocha stave. I recently tasted two attempts. One of the resulting bourbons was redolent of a Christmas spiced whiskey — it would have worked perfectly in an egg nog. The other was so smoky I wouldn’t have been surprised if it was single malt. I enjoyed both, but Bowie and her panel didn’t. Neither stave will ever join the Private Select program or hit the market.

There was one recent success story from these ongoing trials, though. Bowie and her team used a stave called Seared Bu 1-3 in an attempt to make a “better” Seared French Cuvée, one with a huge mouthfeel and sweet notes of butterscotch and bread pudding. Though the stave technically “worked” and the resulting bourbon was incredible, they worried the spirit didn’t play well with others.

“You start blending it with other staves — oh, no! — it was awful, it was a bully, it suffocated the other staves,” Bowie says, meaning its flavor notes completely dominated. “Two wrongs make a right sometimes and two rights sometimes make a wrong. Everybody loved Bu, but it doesn’t work for this purpose, so it’s got to go.”

Still, since it was so good, Maker’s Mark didn’t want to keep it entirely off the market among the other hand-labeled bottles lining Bowie’s office. So the company released 1,400 375-milliliter bottles of it at its Loretto, Ky., gift shop in April 2019; it sold out in two days. This is a sales avenue for a singular stave that you might start seeing more of in the future.

Until then, Bowie and her team and Independent Stave will continue conducting wood experiments, trying to amplify flavors in bourbon. Staves will be re-worked, others will evolve, and new flavors will be pursued. And the program will continue to create plenty of other bourbons that taste like marshmallows or cotton candy or, yes, mesquite potato chips — and which most of us will probably never taste.

“By now we understand what natural flavors you can get out of wood,” Bowie says. “What we still don’t know is how far you can take it.”