In 2012, Westport, Conn., resident Nick Shields was sitting in a local dive bar when he noticed five women order vodka sodas one after the other. An entrepreneurial type in his late 30s, with considerable experience in the booze industry already under his belt, Shields was struck with an idea: What if he came up with a packaged, ready-to-drink version of the cocktail he could sell in supermarkets rather than bars?

Perhaps because of his family’s legacy in beer or driven by the financial and distribution advantages of selling beer versus hard liquor, Shields created his product from a brewed alcohol base. After more than 100 attempts and one year of trial and improvement, he perfected a recipe that, while it tasted nothing like an IPA or lager — it didn’t particularly taste of anything, for that matter — could be classed and sold as beer. And so launched SpikedSeltzer, which would later rebrand as Bon & Viv, and with it the runaway hard seltzer train. The category is now worth over $4 billion in the American alcohol market annually.

While Shields created a commercially viable packaged vodka soda — long before anyone started talking about canned cocktails or began using acronyms like RTD — the fact remains that for home drinkers, the easiest way of recreating the dive-bar staple is making just that: a vodka soda. For flavored iterations, we need only turn to La Croix, Spindrift, and the plethora of other lightly fruity, sparkling waters on the market.

Homebrewers did not get this memo. Or better put, most are no doubt aware of this, but that hasn’t stopped them from taking on the very same challenge as Shields.

In online forums such as the r/Homebrewing subreddit, users debate the merits of different yeast strains and nutrients for brewing hard seltzer and troubleshoot issues like achieving crystal clarity for their DIY White Claws.

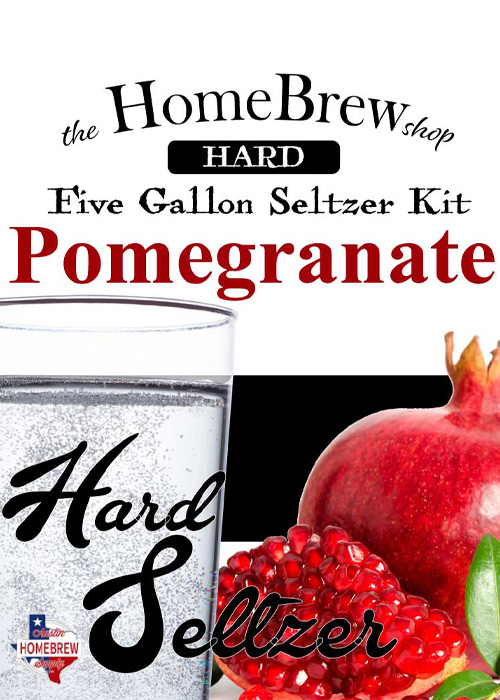

Homebrew supply companies have quickly cottoned on to the phenomenon, too. Retailers like Austin Homebrew Supply now offer recipe kits with all the ingredients needed to recreate market-leading brands. Provided they are armed with some pretty basic brewing equipment, for around $20 amateurs can cook up 5 gallons of hard seltzer — the equivalent of more than 50 12-ounce cans.

The kits typically include some form of sugar, which provides the base for fermentation, as well as yeast, nutrients, flavorings, and occasionally a fining agent for clarification. The process is as simple as dissolving the sugar in water, adding the yeast and nutrients, and leaving the mixture to ferment for between five and 10 days. Brewers then add the (optional) fining agent, flavor the boozy-but-flat water, and finally carbonate it after transferring to bottles or a keg — no Tito’s, no Canada Dry necessary.

Within the broader realm of homebrewing, which was federally legalized in 1978, seltzer remains in its infancy. Where craft beer producers share “clone” recipes for their brews with online publications and organizations such as the American Homebrewers Association (AHA), the White Claws and Trulys of this world aren’t sharing too many secrets.

The AHA does offer its own recipe for homebrewing seltzer, and its parent organization, the Brewers Association, published a book on the topic in 2020. Authored by Chris Colby, “How to Make Hard Seltzer: Refreshing Recipes for Sparkling Libations” scales down industrial recipes so that they can be used by small craft producers and home fermentationists alike. (Budding brewers can also turn to VinePair contributor Mandy Naglich’s homebrew column for excellent advice on the topic.)

But it is in online forums where the most animated discussions take place, and where the most useful, on-hand advice is shared.

Peruse the many threads on the topic in the r/Homebrewing and you will quickly learn that the best means of achieving Truly-esque fizz is through force-carbonating a kegged, fermented base rather than carrying out a secondary fermentation in a sealed drinking vessel, otherwise known as bottle conditioning.

You will also soon become well versed in the combined merits of cold crashing (chilling down the fully fermented brew to separate solid particles) and using fining agents such as Chitosan to achieve near-crystal clarity. Yet most homebrewers argue this is something of an overkill, and almost nobody is investing in fancy professional filtering equipment.

If you do spend some time in these threads, it’s possible you will eventually be hit with the same realization I was — that homebrewing hard seltzer seems somewhat contradictory in nature.

A large proportion of homebrewers would surely sooner drink complex sour ale or a hoppy, hazy IPA than a White Claw or Truly. And while simple in principle, achieving a commercial standard of hard seltzer relies on a certain level of knowledge and experience, not to mention equipment such as kegs and carbonation rigs.

So who exactly is homebrewing hard seltzer, and, more importantly, why go to all the effort?

For some, it all boils down to the challenge. Colby, the author of “How to Make Hard Seltzer,” says brewers have to be “firing on all cylinders to make a decent hard seltzer.” And because of this, he thinks a good number of those making hard seltzers are doing so to test their brewing mettle.

His theory aligns with multiple conversations I’ve had with brewing enthusiasts — homebrewers like David Buchanan, a Utah-based software product manager. Buchanan says that after five years of homebrewing, he recently made his first batch of hard seltzer just to see whether he could actually do it. “Homebrewers are willing to try anything,” he says. “And if they get that itch, they want to scratch it.”

For Buchanan, the advantages of making his striking “Blue Hawaiian Hard Seltzer” went beyond the satisfaction of ticking the style off a list of successful brews. While he is an occasional summer seltzer drinker, the brew piqued the interest of his wife, who enjoys hard seltzer more than he does. Given that she isn’t much of a “hop head,” Buchanan’s homebrews don’t always offer that appeal.

For those making hard seltzer for their own personal consumption, there are added incentives. Nick Robbins, a web content manager based in San Luis Obispo, Calif., regularly has a kegged batch of seltzer on hand at home. Asked why he first started making the style, he says it’s “all about the cost.”

Why spend close to 20 bucks on a 12-pack of hard seltzer from his local grocery store, he says, when he can make a 5-gallon batch at home for under $10?

Robbins admits that the cost of brewing hard seltzer only drops this low because he already owns all the necessary equipment and has ingredients such as Champagne yeast on hand. Still, he’s not the only one for whom this is true and Robbins says homebrewing hard seltzers is “definitely” catching on, in part due to its relative simplicity but also because of how popular the category is right now.

New-York-based homebrewer Sheri Lyn Jewhurst told me she started making seltzer a few years ago as an experiment. At the time, she had no idea hard seltzer existed and was instead simply curious to find out what would happen if she brewed sugar, yeast, water, and fruit together. (She calls her invention “Booze Soda” and laments the missed business opportunity.)

Spokane, Wash.’s Jeff Clark has been homebrewing since 2011 and brewing commercially (on a very small scale) since 2019. Initially skeptical about hard seltzer, he decided to start brewing the style because he was convinced he could make a quality “craft” alternative to the mass market leaders.

Though he does so now as a licensed brewer, it’s hard not to draw parallels between that philosophy and the very genesis of homebrewing. Back in the day, if you wanted a better beer than those produced by national-scale breweries, you pretty much had to make it for yourself.

After multiple conversations with hard seltzer homebrewers, there comes a point where you find yourself pondering whether the question is instead “why not?”

Each shared experience dials into the adage that life is just as much about the journey as the destination. Incredibly corny though that sounds, it speaks to the very same phenomena witnessed in early quarantine pandemic life. I, for one, am among those guilty of taking on just about every project I could find in the early days of stay-at-home life, from baking sourdough and fermenting hot sauce to freezing breeze-block-sized cuboids of clear ice.

In the case of recreating hard seltzer: Sure, it would be easier, faster, and — for most of us — considerably cheaper to pick up a bottle of New Amsterdam and a 12-pack of Pamplemousse LaCroix. But where’s the fun in that?