Asking whether a column still or a pot still makes better spirits isn’t a fair question, because if one did, and was universally recognized as doing so, it would be the still clearly favored by the majority of the spirits-producing industry, but that’s not the case. Do they make different spirits, though? Yes, and that difference is what causes some producers to prefer column stills and others to prefer pot stills.

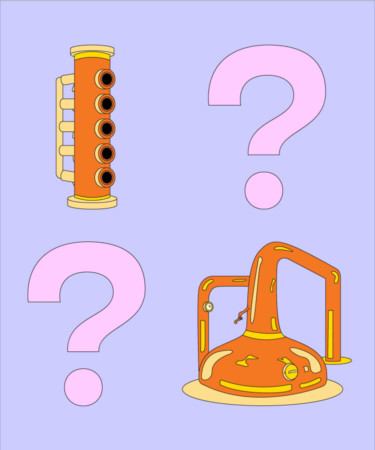

Pot stills are by far the older of the two kinds of stills. They were invented in the 15th century as an evolution of an earlier still, the alembic still, that was used to make alcohol starting in the 9th century. These stills are almost always made of copper and look exactly the way you’d imagine: a large cauldron with a swan neck that comes out of the top like a spout and leads to a coiled condenser.

Column stills are the more industrial type of the two, and came about four centuries later than pot stills, in the 19th century. Column stills are of a tall, slender build with the inside of the still containing multiple chambers stacked on top of each other. These stills are sometimes made of copper, but can be found just as often made from stainless steel.

Column stills are known to create a very pure distillate. It’s for this reason that column stills are used most often to produce spirits like gin — which has botanicals added to it and so starts with a pure base spirit — and vodka, which most people want to be tasteless. Pot stills, on the other hand, create a distillate with more congeners — and therefore, more flavor — and are used for spirits like whiskey, tequila, mezcal, rum, and Cognac.

Because the pot still has this association with flavor, it has gained a reputation as being more “craft” than the column still. It also helps that it’s much older than the column still, and therefore is sometimes said to make “better” spirits. But this isn’t totally true. There are some delicious rums and whiskeys that are made using column stills, and some bad ones made from pot stills. At the end of the day, it all comes down to the skill of the distiller and the treatment of the resulting liquid.