There are more than 4,000 craft breweries operating in America, more than at any other time in our gloriously tipsy history. And it can be conservatively estimated that if we have 4,000-plus breweries, then there are upwards of 40,000 distinct beers on the market at any given time. Among its portfolio of at least five dozen beers, Samuel Adams sells 10 different winter seasonals, plus five IPAs with “Rebel” in the name; Stone offers eight Arrogant Bastard variants. There’s a lot of beer out there!

This can make a trip to your friendly neighborhood 100-draft beer bar as confusing as it is delicious. Even if the menu is meticulously updated (and it’s not), who’s got the discipline to read for 15 minutes before her first sip of beer? Sure, you could just ask for “Whichever Bastard you got, they’re all the same to me,” but a safer strategy is to quickly scan the tap handles for a brewery you like and then ask your bartender which specific beer’s in the barrel.

This, of course, requires breweries to design, manufacture, and distribute distinctive tap handles. Some who embrace the aesthetic side of the game may relish these tasks, but it can be a chore for those who don’t enjoy adding “arts and” to the craft beer life. But even if some breweries don’t think tap-handle design is fun, they all know it beats buying advertising. Boston Beer Company has television ads, and Lagunitas sponsors “This American Life,” but for the most part craft brewers try to get by without spending money on media.

So tap handles it is. Now, how to make one that stands apart from the crowd? The simplest, lamest, craft-beer-needs-more-women-in-decision-making-capacities-provingest route to making your brewery’s handle rise above the rest is to make it rise above the rest. Yup, just go with the longest, strongest beer-dong you can muster in hopes of appealing to the red Mustang gang, plus all the customers who choose a beer by first staring at the ceiling and then steadily lowering their eyes until a beer tap comes into view.

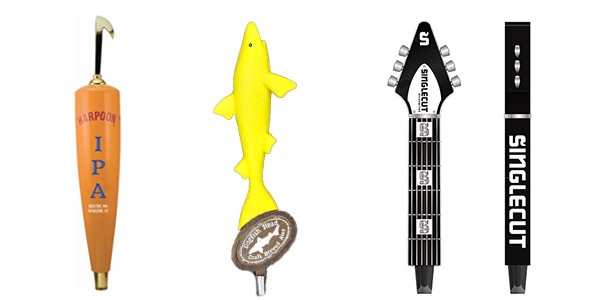

Or maybe go in a more interesting and tasteful direction. Mid-Atlantic weird beer pioneers Dogfish Head of Milton, Delaware, were at the forefront of the “Wait, it doesn’t just have to be a stick with your name on it?” tap handle movement when they introduced their now-iconic shark-topped model in 1998. Harpoon Brewing went a similar direction by tacking their namesake stabbing-stick atop their tap handles, though it’s less noticeable than the Dogfish Head rendition on account of the fact that harpoons aren’t as wide as sharks. Which is more than fair when it comes to man-versus-sea-beast showdowns, but an impediment in the ferocious land-based battle for craft beer market share.

SingleCut BeerSmiths in Astoria, Queens, are also taking the on-the-nose approach. The brewery’s name refers to a style of guitar, and most of the beers pay homage to their rock-and-roll heroes (try the exemplary Billy Full-Stack, named for Cult guitarist Billy Duffy). So, what’s on the tap handles? Guitars of the bitchin’est order, of course.

But small breweries need to be careful when selecting distinctive tap handles, lest they get anchored to a design that can’t be scaled up as they grow into medium-sized breweries. Jack’s Abby, of Framingham, Massachusetts, recently moved into a bigger brewery following four years of rapid growth. Which is great! But what’s it mean for their beloved tap handles, which currently feature three spinning copper-plated rings surrounding a nameplate. It means they’re being retired.

According to Jack’s Abby sales manager Ben Warner, the first generation of the handles he affectionately refers to as “spinners” was manufactured in China, which required a three-month lead time on orders. This became untenable for a growing brewery, so the job was in-sourced to a manufacturer in Vermont, raising costs to about $30 to $35 per handle.

Warner estimates that 95 percent of bars carrying his beer require tap handles, and 75 percent of those need more than one. “Sometimes a bar will do a tap takeover, go from one draft line to seven, which is great, no problem, we happily provide another six handles.” But then the next week, when that bar goes back down to one Jack’s Abby draft, the handles don’t always find their way back home. As the brewery grew, the quirky tap handle racket became untenable.

Warner estimates that 95 percent of bars carrying his beer require tap handles, and 75 percent of those need more than one. “Sometimes a bar will do a tap takeover, go from one draft line to seven, which is great, no problem, we happily provide another six handles.” But then the next week, when that bar goes back down to one Jack’s Abby draft, the handles don’t always find their way back home. As the brewery grew, the quirky tap handle racket became untenable.

The brewery’s post-expansion rebranding includes switching from the copper-plated spinning handles to more traditional poly-resin ones. “I’ll always love the spinners, but they’re just not practical at a certain scale,” Warner says, adding that the new design is partially inspired by the utilitarian elegance of Allagash Brewing’s wooden handles.

Kent Falls Brewing is in their second year of production on a former dairy farm in Kent, Connecticut. Kent Falls is thriving, having recently broken into the Boston and New York markets, but they have no plans to abandon their bespoke tap handles. Each hook-shaped metal handle is handmade out of conveyor-belt chain salvaged from the on-site barn. There are currently about 300 handles in service, with enough chain left to forge another 50 or so, thanks in part to a recent donation from their friends at the nearby, soon-to-open Fox Farm Brewery. When asked what he intends to do when they run out of chain, Kent Falls owner Barry Labendz said, “Unfortunately, there are a lot of defunct farms in this area. We’ll find more chain, and we’ll make more tap handles.”