![All the Flavors and Aromas in Your PATRÓN Tequila [Infographic]](http://vinepair.com/wp-content/themes/vpcontent/images/blank.gif)

This article is part of a series, highlighting the importance of additive-free and authentic tequila, partnered by PATRÓN. Discover more at The World of PATRÓN.

There are many factors that set PATRÓN apart amid the increasingly crowded tequila market, but none are as important as how PATRÓN is made. As the category leader, PATRÓN Tequila does not compromise quality for efficiencies and is one of the only tequila brands that has remained dedicated to a traditional, handcrafted process since the brand’s inception.

One of the few brands that still makes tequila the hard way, by hand without artificial flavorings or ingredients, PATRÓN stays true to time-honored, traditional production methods using only a few natural ingredients. Coupled together, these elements when masterfully combined create perfection.

From agave field to cooking to bottling, this tireless dedication to perfection is at the core of everything PATRÓN does. The brand uses the highest-quality ingredients and handcrafts its tequila in small batches to ensure consistency and quality in production, with one goal in mind: to create the finest tequila in the world.

There’s no single answer as to what creates the storied flavors and aromas of the brand’s super-premium portfolios of tequilas. Rather, it’s a mix of the finest agricultural ingredients, traditional distillation methods authentic to Mexico, and time spent in unique casks, coupled with a tireless dedication to achieve perfection in every drop by PATRÓN’s familia of bold innovators. These innovators’ unshakable confidence is embedded in the heart and soul of PATRÓN and leads to a simply perfect tequila.

While different PATRÓN expressions will be impacted primarily by how they are aged, they all begin with agave. PATRÓN only uses hand-selected, ripe 100 percent Weber Blue Agave, which is roasted for a full 72 hours before distillation. The brand has used the same small brick ovens roasting slowly over the course of three days to extract the most balanced flavors from the agave. While this three-day roasting process is 50 hours longer than the industry average, it pays off by providing PATRÓN Tequila with a more complex flavor profile.

Once the roasting process has succeeded in converting the agave’s starch content to sugar, the plants are crushed using a roller mill and the “tahona method,” an age-old practice that relies on 2-ton volcanic stones. While the tahona method is not as quick or convenient as modern, industrialized methods — which is why PATRÓN is one of only a few tequila distillers that utilize it today — it’s in keeping with PATRÓN’s commitment to slower, time-honored practices that, in this case, yield a smooth yet complex tequila.

After the roller mill and tahona method have kick-started the agave’s fermentation process, the resulting liquid is distilled in copper pot stills that are smaller than the industry standard. The decreased surface area allows for more interaction with the spirit, and, in turn, generates more flavor.

After the distillation process, the tequila may be aged in unique casks at different intervals of time to create deeper, richer, and more complex flavors and aromas depending on the particular expression of PATRÓN that is being created.

This precise and time-honored production process yields a tequila of the highest standard of quality. But the attention to detail doesn’t end there. Regardless of expression, the tequila is eventually bottled, hand-labeled, and even corked by hand to complete a process that places the quality of the final product above all else.

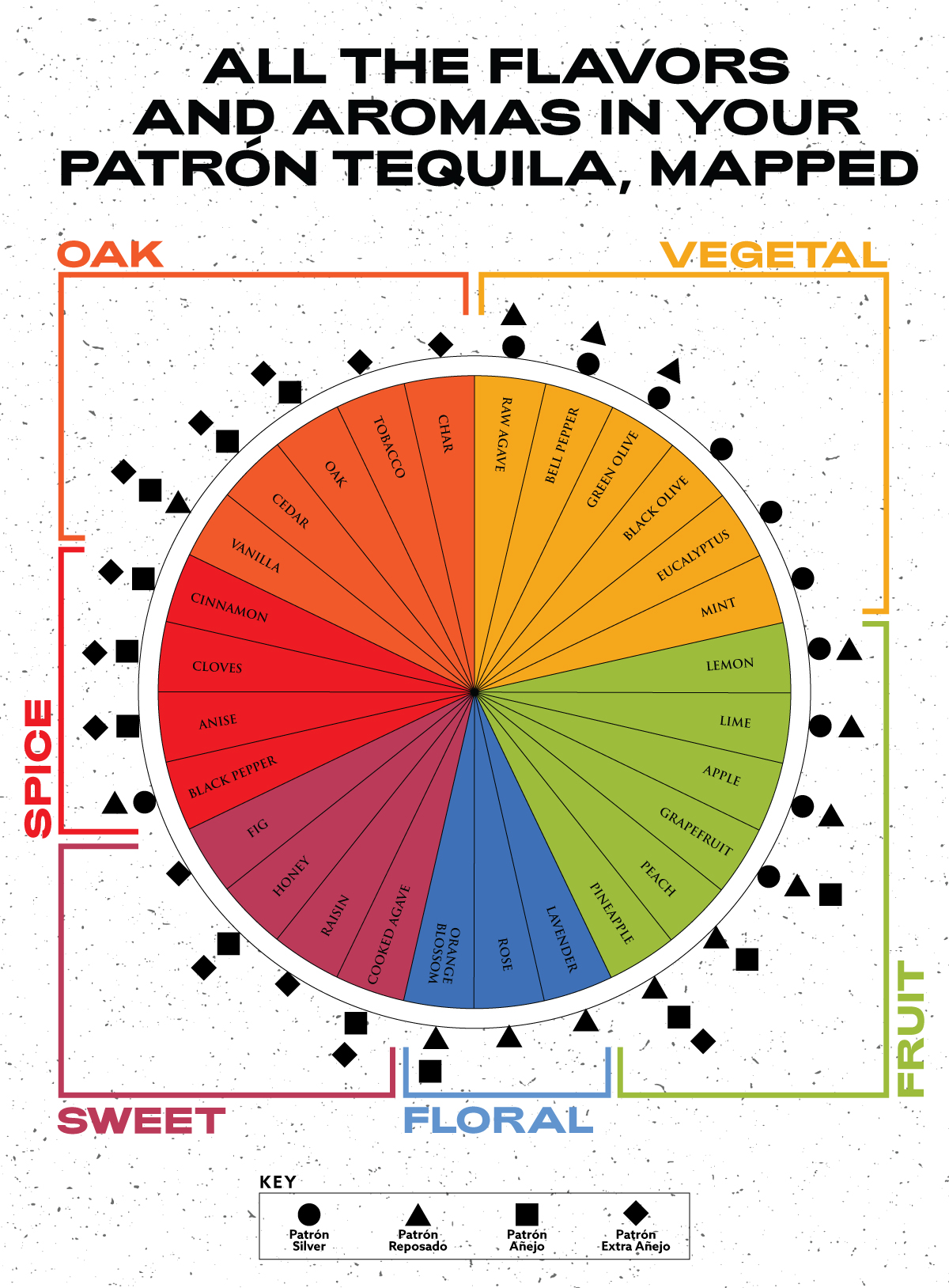

Now that we’ve given you a behind-the-scenes look at how PATRÓN is crafted by hand, we invite you to explore the infographic below to learn a little more about how each PATRÓN expression receives its particular flavors and aromas through every stage of the tequila-making process.

This article is sponsored by PATRÓN.

![A quick guide to learn about how each PATRÓN expression receives its particular flavors and aromas through every stage of the tequila-making process. All the Flavors and Aromas in Your PATRÓN Tequila [Infographic]](https://vinepair.com/wp-content/uploads/2022/01/patron_article19_flavormapinfographic_mobile-640x640.jpg)