On Dec. 31, 1759, Arthur Guinness signed a 9,000-year lease for a 90-foot-by-300-foot brewery. Over the years, his beer, Guinness, grew to become one of the most widely produced beers in the world and turned into a storied national emblem.

Today, the St. James’s Gate brewery is a massive complex with a showroom, restaurant, seven-floor storehouse, and a gift shop. But back in 1902, it was just a humble mega brewery with workmanlike focus producing one twentieth of the beer made in the United Kingdom. Photos from that time period taken by Ireland’s Department of Agriculture and Technical Instruction and published in the manual “Ireland: Industrial and Agricultural” in 1902 show a simpler time in Guinness’s history.

“In 1860 the premises occupied by the brewery covered about four acres, but in proportion as its trade increased, the firm gradually acquired the ground adjacent to it, in order to carry out the extensions required,” the manual reads. “The buildings are composed of two principal parts, the old brewery and the new brewery, which was built in 1879 and subsequently extended to meet the growing demand for accommodation, and the premises to-day occupy more than forty acres, and are constantly being still further extended.”

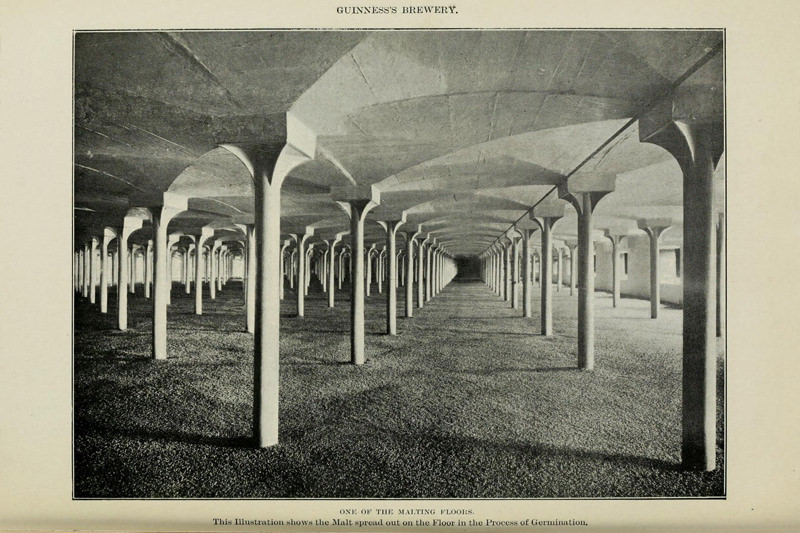

The cavernous malting floors on the second level of the brewery where barley was spread to germinate and dry out. Alongside the maltings were grain stores, a vat house, and other offices. Back then, Guinness only brewed a porter, Extra Stout, Export Stout, and Foreign Stout.

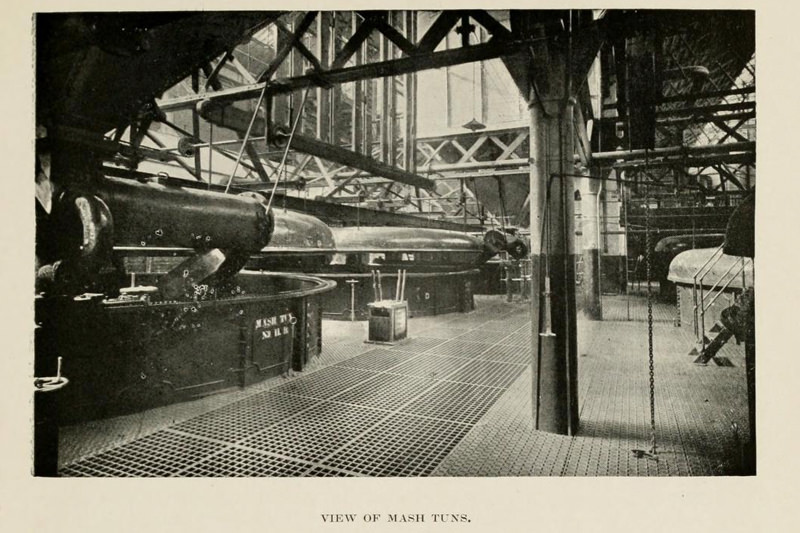

The beer starts in the mash tuns, where a process called mashing converts starches into sugars for fermentation. Around 37 million barrels of beer were made by some 6,440 brewers in the U.K. in 1900, and 1.85 million of that was made by Guinness. The “Ireland: Industrial and Agricultural” manual speculated that Guinness “have by far the largest output of any firm in the United Kingdom or, indeed, in the world.”

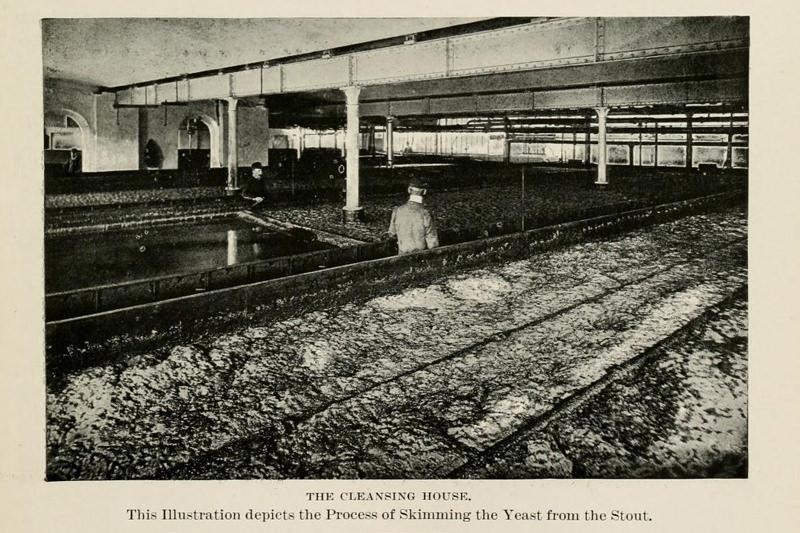

On the third floor (“about sixty feet above the river quay,” as the manual puts it) were the fermenting rooms, vat houses, tables, and the malt and hop stores. It was where the magic happened, where the yeast turned sugars into alcohol.

Even though it was high up, the fermenting rooms were never far away. The levels of the brewery were connected by miniature railway lines with a 22-inch gauge and 15 engines. There were 40 branch stations of telephone and telegraph offices throughout the brewery, and a pneumatic dispatch system to transmit letters from one department to another.

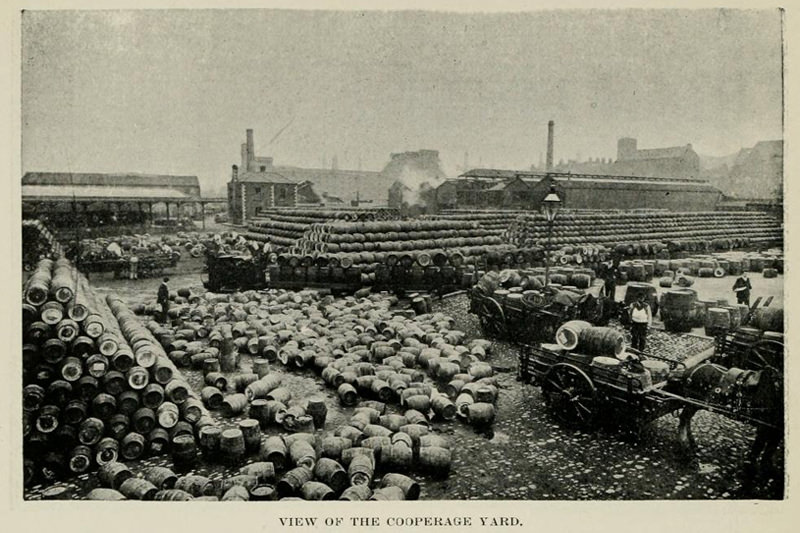

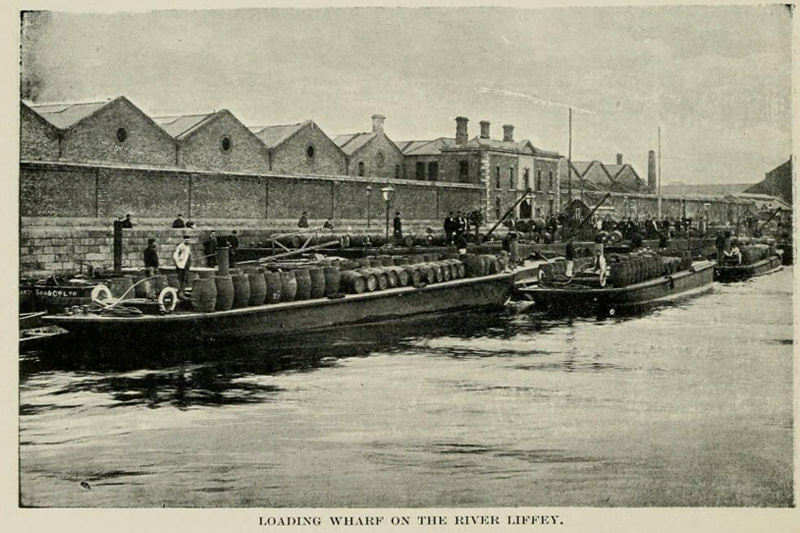

Outside the brewery and on the lowest level were the carpentry, cooperage shops, the cask washing sheds, the racking and filling stores, as well as the platforms where the beer was loaded for transport.

The beer was pumped into oak casks made by coopers at the brewery and then sent around the world. On the ground floor, you could run into “engineers, machinists, farriers, carpenters, joiners, brasiers, plumbers, painters, and other artisans for the repairs necessary to the machinery and general plant are done by the workmen employed by the brewer, and over 50,000 casks were made last year.”

The Guinness left the brewery by sea or by land. The brewery owned at the time 160 drays (low carts) and floats, 153 horses, nine steamers, and five “motor trucks.”