Like Champagne and sparkling wine, and Parmigiano Reggiano and parmesan, real, traditionally made balsamic vinegar is a victim of genericization. While the term has become attached to acidic, watered-down salad seasonings, the $5 bottles stacked on supermarket shelves bear zero resemblance to the vinegar in its finest inky form: Aceto Balsamico Tradizionale di Modena DOP (Traditional Balsamic Vinegar of Modena PDO).

Generic balsamic vinegars can be produced anywhere in the world, but Balsamico Tradizionale di Modena must be made in the province of Modena in Italy’s Emilia-Romagna region. Along with the region’s other traditionally made, geographically protected vinegar (Aceto Balsamico Tradizionale di Reggio Emilia DOP), the liquid “black gold” is produced under strict guidelines, guaranteeing the highest end quality.

As anyone who is lucky enough to have sampled it can attest: It’s time and effort well spent.

Balsamico Tradizionale bears the luscious sweetness and piercing acidity of the world’s finest dessert wines. Its bouquet rivals white truffles in aromatic intensity. Its flavor is so complex and concentrated that a few small drops elevate a slice of fruit, chunk of cheese, or a bowl of creamy risotto into something memorable.

From vineyard yields and harvesting ripenesses, to fermentation, acetification, and maturation, this is how the world’s finest vinegar is made.

Grapes

Only the varieties permitted for production of Modena DOC wines can be used to make Balsamico Tradizionale. The seven-strong list of grapes most notably includes red variety Lambrusco and white variety Trebbiano. All must be cultivated in the province of Modena.

To ensure the highest quality of raw ingredients, the grapes have to ripen to a minimum level of 15 degrees Brix before harvesting. Vineyard yields are also capped at 160 quintals per hectare (roughly 6,400 kilograms per acre).

Production

Production of Balsamico Tradizionale follows a three-step process. The first sees the pressed grape juice (called “must”) cooked in an open vessel for between 12 and 24 hours, at a minimum temperature of 176 degrees Fahrenheit. Cooking continues until the must is boiled down to around 30 percent of its original volume and the Brix level reaches at least 30 degrees.

The cooked must is then ready to be converted to vinegar. While stored in large wooden casks, or badessas, naturally occurring yeasts convert some of the liquid’s concentrated sugar content to alcohol. This alcohol is then transformed into acetic acid by bacteria, completing the transformation of must to vinegar. The entire process takes around one year, at which point the vinegar is ready for the third and most important stage of production: maturation.

Aging

Balsamico Tradizionale ages for a minimum of 12 years before release. Over that time, evaporation reduces the vinegar to its signature syrupy texture, while oxidation develops the vinegar’s intense aromas and complex flavor profile. Aging occurs in a series of wooden barrels, collectively known as a batteria (battery). The process is very similar to the solera method used to make sherry.

Each battery contains a minimum of three barrels, though most are made up of five or seven different casks. Each cask is a different size and can be made from a range of woods native to the region, including oak, chestnut, acacia, ash, cherry, mulberry, and juniper. The combination of barrel sizes and materials, as well as the conditions in the acetaie tradizionali (aging rooms), create a unique flavor profile for each battery.

Organized in descending order from large to small, the vinegar starts its maturation journey in the largest of the series, while the finished balsamico is eventually removed from the smallest. Whenever balsamico is withdrawn, each barrel receives a portion of liquid from the next largest in line, while the first barrel is topped with the vinegar from the badessa.

Because oxygen plays an integral part in the aging process, barrels are only ever filled to around three quarters of their capacity. Rectangular openings on the top of the casks also aid the oxidation process. Never fully sealed, the openings are instead covered with a piece of cloth and a loose-fitting stone or slab of wood to ward off unwanted visitors (flies).

Quality Control

Before they can release their viscous dark nectar, producers must send the total volume they wish to sell to the Consorzio (consortium) for evaluation. A panel of experts blind-tastes the sample, scoring it on a number of factors including color, density, aroma, flavor, and acidity. If it’s not deemed ready, the vinegar is returned to the final, smallest cask for additional aging. If it meets the organoleptic criteria, the vinegar is bottled and sealed by the Consorzio.

Bottles

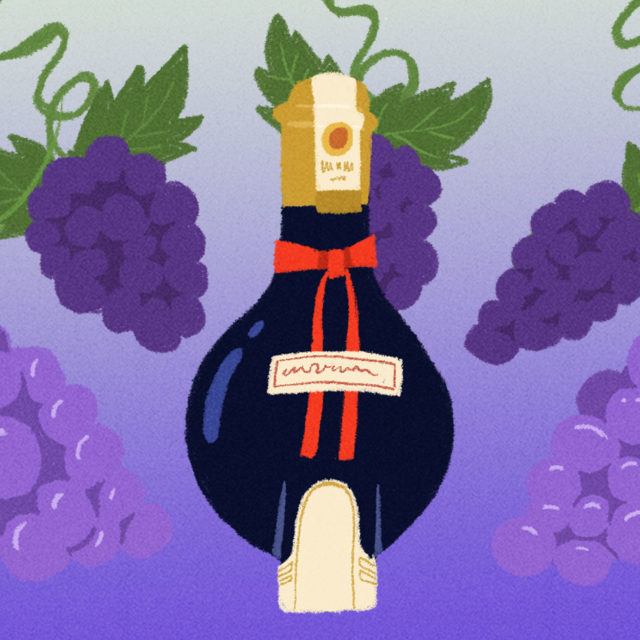

Balsamico Tradizionale is sold in clear, spherical glass bottles with a rectangular base. Only this specific type of bottle is allowed and producers are identifiable by a small label stuck onto the lower front of the bottle. While typically sold in 100-milliliter bottles, 200- and 400-milliliter versions are also permitted.

The age of the vinegar can be distinguished by the color of the bottle cap: White caps indicate a 12-year-old balsamico, while gold represents 25 years of aging. In reality, these numbers are a calculated average of the bottled product. A good proportion of the Balsamico Tradizionale will actually be older than the age statement.